Introduction of High Pressure Boiler Tubes Conforming to National Standard GB5310

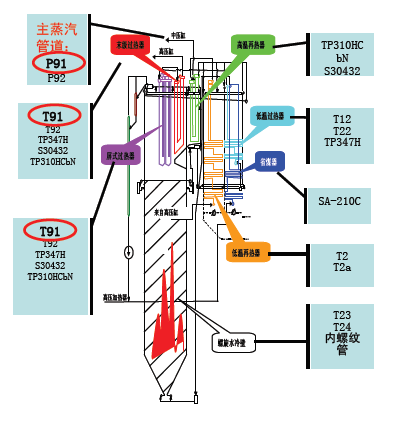

As the high pressure boiler tubes are applied in high temperature as well as high pressure conditions, oxidation and corrosion will occur on the tubes. So, the high pressure boiler tubes are required to have high creep rupture strength , high anti-oxidation corrosion resistance and stable microstructure. The high pressure boiler tubes are mainly applied on the super heaters, reheaters, water walls, economizers of the super critical and ultra super critical boilers.

Changbao’s products are with completed grades, good property, and Changbao can manufacture both heavy thickness tubes with WT/OD ratio up to 36% and thin thickness tubes with WT/OD ratio up to 4%.

Changbao’s products apply mature piercing process, unique cold finish technique, advanced lubrication process, stable and reliable heat treatment technique, ect, and Changbao overcomes ultra super critical conditions with high temperature, high pressure and high vapor corrosion, which shall reduce the construction cycle of the thermal power plant, making contributions to reduce the cost and improve the efficiency of the power industry.

Our products were supplied to world class boiler makers and applied on thermal power projects in domestic as well as international market.

The Grade Conforming to National Standard which we manufacture

20G 、20MnG、25MnG、15MoG、20MoG、12CrMoG 、12Cr2MoG 、15CrMoG、12Cr1MoVG、12Cr2MoWVTiB、10Cr9Mo1VNbN

Standard(Part)

GB5310-2008