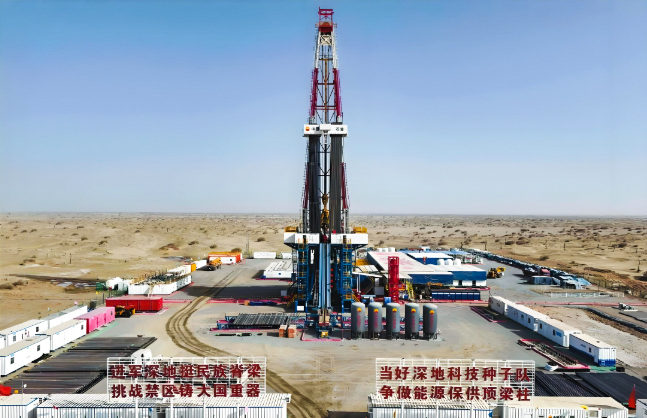

Recently, China’s first 10,000-meter-class scientific exploration well --- Shenditake 1 --- has successfully completed its drilling operation in the hinterland of the Taklamakan Desert in Xinjiang. With a designed depth of 11,100 meters, it has set a record as the deepest vertical well in Asia and the second-deepest across the world. As a key supplier for the project, Changbao’s independently developed ultra-thick-walled tubing with high strength and sulfur-resistant properties, called “CBS3”, has demonstrated its stability throughout the operation in the well by standard torque curves and clear inflection points, ensuring the successful operation of the tubing without any malfunction under extreme operating conditions and earning high recognition from the drilling team, well testing supervisors, and tubing engineering team.

In this project, Changbao has not only provided high-performance products, but also built an integrated service system covering “Sales - R&D - Production - Technical Services”. The sales end has accurately addressed demands: a technical team has been stationed at the well six months in advance for research, enabling customized design of tubing specifications and performance parameters; the R&D end has broken through technical barriers: in response to the needs of ultra-deep drilling, it has developed the specialized CBS3 series tubing, which has passed the API 5CT certification and the special working condition verification of China National Petroleum Corporation (abbreviated as “CNPC”); the production end has strictly controlled quality: full-process digital monitoring has been adopted to ensure that every single tubing 100% passes 28 quality inspections including ultrasonic flaw detection and hydrostatic testing; the after-sales end has provided full-process support: led by the company’s leaders, multiple team members have been stationed at the well on 24-hour shifts to optimize the running-in program in real time.

During the project implementation, Changbao’s technical service team has collaborated closely with CNPC’s team, providing full-process technical support covering tubing selection, running-in program optimization, and real-time data monitoring. This “product + service” dual-driving model has not only verified the professionalism of Changbao’s supporting services, but also significantly enhanced oilfield customers’ trust in domestic high-end steel tubes.

The breakthrough of the Shenditake 1 has provided key data support for CNPC’s ultra-deep oil and gas development, planning and geological research, while the application of Changbao’s CBS3 tubing has demonstrated the solid strength in the technical direction of tubing manufacturing. The successful practice of this 10,000-meter deep well will also become a milestone for the company in the development of pipes for deep-earth engineering. In the future, the company will continue to focus on customer needs, promoting the iteration and upgrading of high-strength, high-toughness and corrosion-resistant pipes, and contributing to the national energy strategy with high-quality products and services, so as to forge the brand of “Changbao”.

View More(Total0)Comment Lists