As oil production environment changes, requirements on the connection strength and sealing performance are much higher in deep well, ultra deep well, high-pressure gas wells, thermal production wells, extended reach wells and complex formation structure wells.

API round thread sealing type has poor performance, the connection strength of threading section is only 60%-80% of tube body strength. Although the strength of API buttress thread is higher while its seal performance is very poor.

Most of the premium connection used in China are imported, only few companies develop and produce such product. The research of premium connection started from Vallourec in 1960s, until now there are more than 30 companies which has developed similar connection, with more than 100 patented products, which are suitable for various conditions of drilling and production. Premium connection were widely used more than 22% of total OCTG, more than 60% in Europe.

To meet the requirements both on the connection strength and sealing performance, ChangBao developed CB series premium connection. At the same time Changbao cooperated with some oversea companies and developed various premium connections which can be used in various service environment. Changbao premium connections for tubing and casing have been applied in many domestic oil field such as Daqing, Jilin, Dagan, Changqing, Xinan, Shengli, Jidong. Overseas Rosnel, Lukoil, Petroecuador, TNK-BP, Ecopetrol, PDVSA and other oil companies have also applied Changbao premium connections.

Definition method of Changbao premium connection:

CB+Function Code+Series Code

CB=Abbreviation of Changbao

S=Seal

X=extreme-line casing

IJ=integral joint tubing

SF=Semi-Flush

HT=High Torque

HC=High Compression

TS= Two-Step-Torque

TSTA=Two-Step-Tapered

HTHP=High Pressure and High Temperature

Series Code: Use number 1,2,3 to represent different type of same category.

Patented premium connections of Changbao:

CBS1、CBS2、CBS3(Qualified by ISO 13679-CAL IV test);CBS3-HC; CBX;CBIJ;CB-EU-HT;CB-SF;CB-FJ;CBTS;

Cooperatively developed connection: Flush-Max,Flash-MaxⅡ/Ⅲ, Super-Max, Super-Max TS/TS2, MO-EU-PA, MO-CSG-PA,GEOCONN

Grade which can be applied to premium connection

Premium connection developed by Changbao can be produced by any steel grade.

Independently developed premium connection

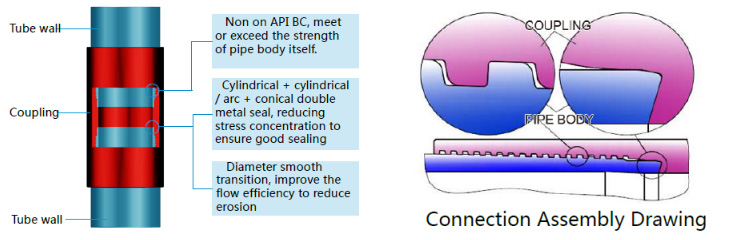

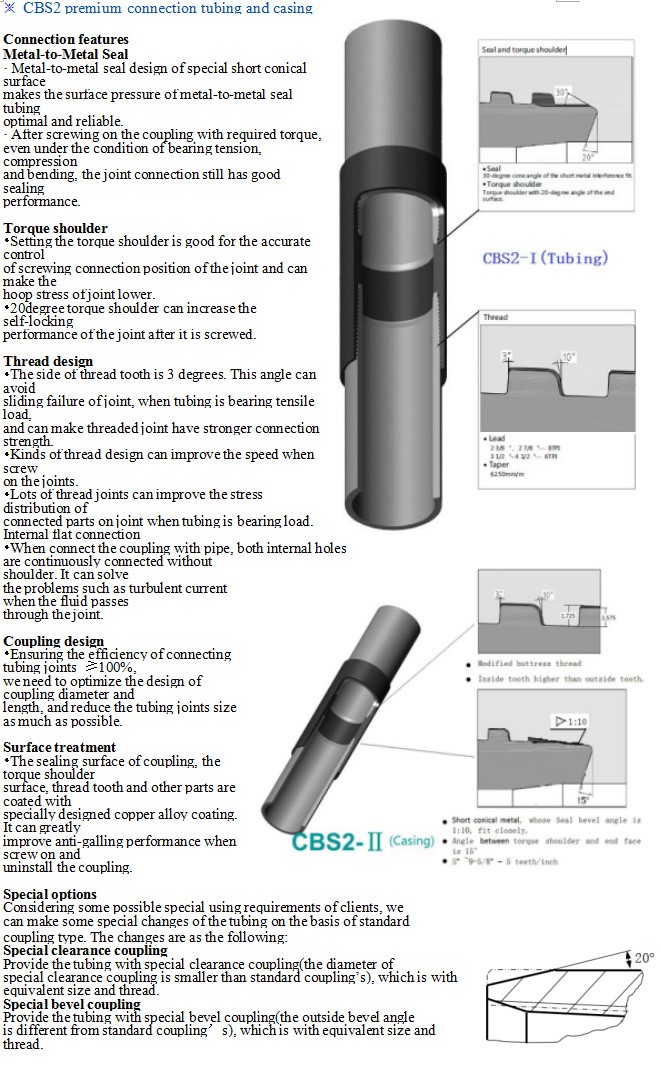

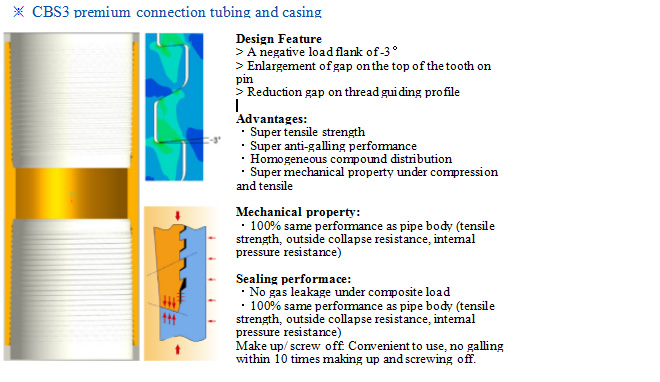

Structural feature of CBS1

Considering about the requirement of domestic and overseas oil and gas well development, Changbao CBS1 premium connection has the features as following:

1) High connection strength – with coupling connected

2) High threading connection strength is – BC thread (8 tooth per inch for tubing, 5 tooth per inch for casing)

3) Excellent sealing performance – Bi-metallic sealing

4) No eddy current and scouring – Inner diameter smooth transition

5) Excellent anti-gluing performance – Coupling thread and sealing surface are electroplated by copper beryllium

Applicable Situation

Deep Well, Ultra Deep Well, High-Pressure Gas Well, Directional Well, Complex Formation Well and other oil gas wells which required high connection strength and sealing performance.

Anti-corrosion Well

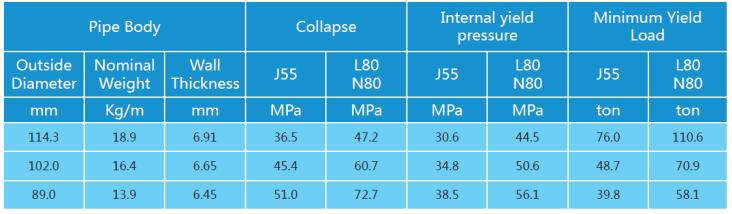

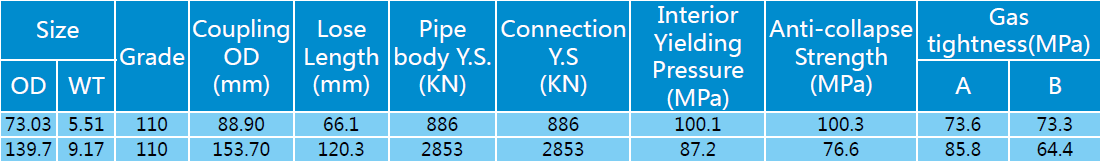

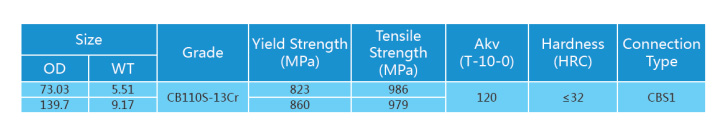

Parameter and Performance of conventional dimension tubing and casing with CBS1 premium connection

Column A in Gas Tightness is the test result according to API RP 5C5 3.3.4 (Final interior pressure cycle & thermal cycle test, thermal cycle temperature is 177℃), column B is the test result according to TGRC1(Gas tightness test on the condition of bending、stretching, bending 20°/30m, combined stress reach 85% of pipe body yielding Pressure)

Performance and Application

Our tubing and casing with Changbao CB110S-13Cr premium connection has been used in CO2 corrosive gas well of CNPC, the performance is listed in following table.

Service environment: Formation pressure 41.4-43.2MPa, formation temperature 122-140°C, CO2 concentration in average 26.77 %, the total mineralized degree of formation water 1215.4-13775.3mg / L, Chloride ion concentration is 3438.9 mg / L.

Inspection report

Cooperative development of Integ-max premium connection

Integ-max premium connection is developed by Changbao and Japanese company Metalone.

This premium connection is mainly used in work of abandoned well, well difficult going in the hole

and big slant well (for example the third biggest Russian oil field TNK-BP), normally used on the

connection part of small size casing and tubing.

Structure features

1).Size scope: 60.32-114.3mm

2).Upset end finish – Outside upset end finish ensures the

connection strength

3).Integral joint – Steel tube applies integral joint without

coupling

4).Double shoulder sealing – The design of double shoulder

resistant excessive torque, ensuring the sealing performance

5).Apply Non-API BC thread, oriented surface 45 degrees,

bearing surface 2 degrees

6).Good bending, gailing performance

7).The surface of box and pin has been treated with

phosphating or sandblasting

Bending model analysis

Buckle(B0)axial stress

Results:

1. Step does not open under bending load down

1) Contact with steps index (SCI) to verify the steps are closed or open:

SCI(ksi-inch)=contact pressure×steps width

2) As long as SCI is positive steps is closed

2. The connection on the axial stress unyielding

Application scope

Directional well, complicated stratal configuration wells require the oil and gas wells with high

connecting intensity and sealability

Abandoned well repair mining

Deep well, ultra deep well, gas well

Using performance

1.Connection Strength

Tensile yield load=80% of pipe body yield strength

Resistance to compression=80% of pipe body yield strength

2.Sealing Performance

Thread seal connections, the mother buckle and male buckle double shoulder seal may also play a

role in sealing function

3.Composite loading capacity

The use of reverse torque and right angle torque shoulder combination, make joint resistance to

compression, bending, torsion resistance ability, at the same time in bending and composite loads,

can still maintain the shoulder on the surface pressure

4.Smooth design can effectively reduce the gas or liquid in the pipe flushing and turbulent flow

phenomenon, reduce the energy loss and erosion.

5.High bending resistance, reached at 45dls/30m

6.Anti-collapsing meets the requirement of API Anti- collapsing pressure

INTEGMAX performance characteristics: